The application of robotics technology to automotive repairs shops has caused nothing short of a revolution in today’s shops. The latest technological fronts involve diagnostic tools and OEM connectivity, as well as repair technology and digital marketing strategies that enable a shop to succeed today and deliver on tomorrow’s consumer’s demands

Given that full automation is not yet feasible, the process is being transformed by creative robot systems, including the following examples.

Telepresence Robots

Telepresence robots have long been used in other industries; they’re just now arriving in automotive Telepresence devices allow users to interact remotely, using video cameras and speakers; and also to control an unmanned aerial vehicle or ‘drone’ (ie, a UAV, or unmanned aerial vehicle).

Although telepresence robots are not yet as well-established in professional environments as other forms of remote work technologies, such as email, video conferencing and messaging that have become popular during the COVID-19 pandemic and among an ageing population, the use of embodiment robots is likely to grow too, and terms such as ‘skyping’ or ‘zoom’ are likely to morph into parlances whose names people use for such embodied forms of connection.

The increasing availability of 5G Internet access has enabled telepresence robots to operate with smaller lag times, and much of the latest IoT sensor technology has been used to improve these robots, enabling them to better model their environment and make more intelligent decisions; depth sensors, in particular, can help these machines to better perceive what’s up ahead, such as obstacles, so that they can better avoid collisions.

Robotic Arms

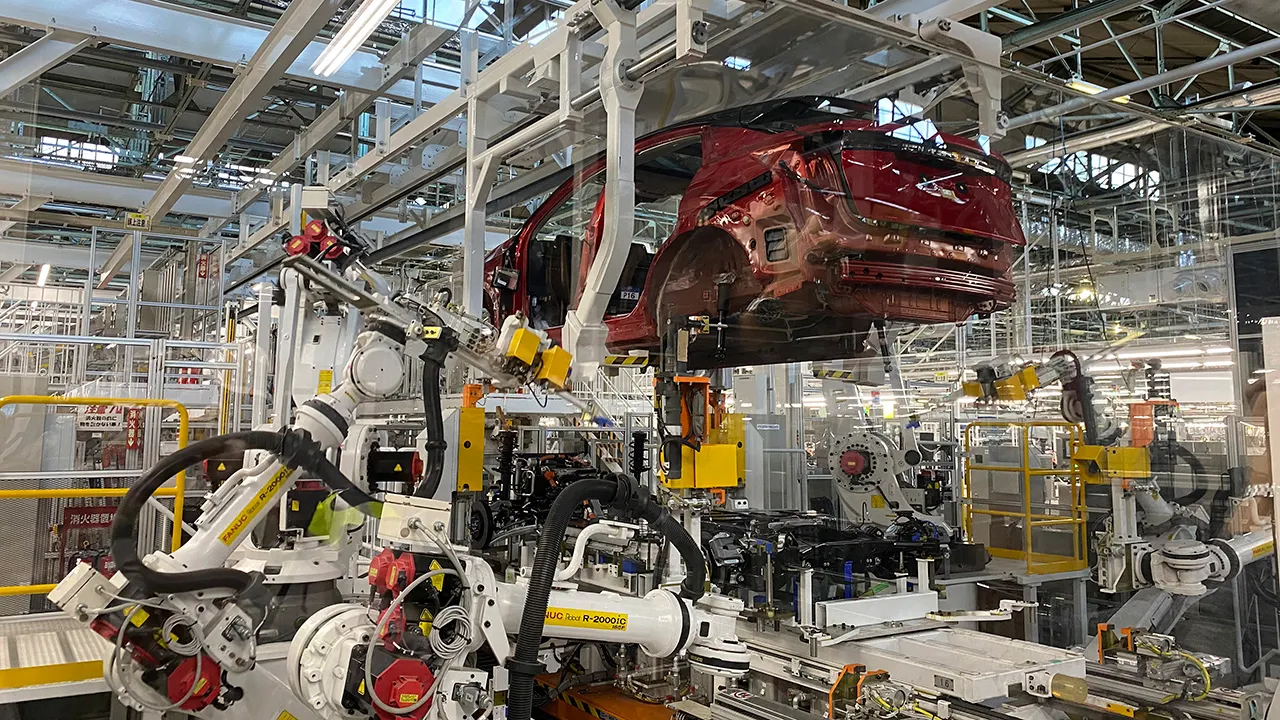

Robotic arms are motor-driven extensions of human limbs that, because they can work fast and perfectly, are well suited to tasks that involve heavy, repetitive or precise work, which it’s hazardous for humans to carry out.

Bear this in mind when thinking of robotic arms: they do not compete with human workers on speed. Instead, they produce the same amounts in the same time window each day, and ensure constant quality on their production lines.

Robotic arms can vary in size and shape depending on their joint articulation, as well as the type of springs or cables used to install them and the size of operating platform.

3D Printing

Robots are to-date leading the process of automation and productivity in manufacturing .Even though these inventions may trigger fears of competition against them, as it could lead to job loss, robots actually raises the productivity and quality by improving efficiencies and consistencies in the manufacturing operations.

Collaborative robots (cobots) can work side by side with human technicians on complex tasks, freeing technicians to focus on higher-value, less repetitive tasks. Because cobots can take over much repetitive manual labour, the risk of workplace injuries is also reduced.

Print-A-Part is designing a device that will 3D print individual parts for auto-parts retailers and repair shops, allowing for the rapid procurement and replacement of needed or damaged car parts. Such supply chain constraints and waiting periods could be substantially reduced.

If an auto repair shop keeps up with the latest technologies, today’s cutting-edge tech could keep you ahead of competitors tomorrow. Call Conceptual Minds today to jumpstart your inbound marketing!

Artificial Intelligence

There are no cars without moving parts, and in the century and a half that cars have existed, body shops have always embraced technology where it makes their businesses more efficient. Data, whether from telematics or from other types of data analytics, allows repair shops to move more expediently and with greater accuracy to address every aspect of the vehicle where a claim has been made.

Robots are increasingly being integrated into the world of automotive manufacturing, including automotive production. Cobots such as the Universal Robotics UR5e can be programmed to do a variety of tasks, ranging from welding and painting to assembly and inspection; robots make good assistants in environments that require working in harmful conditions such as around components with high voltages, or confined spaces.

These innovations are enabling companies to improve their service processes by automating repetitive tasks, enhancing resource utilisation and customer satisfaction, and also offering more predictive maintenance to address costly breakdowns and increase the lifespan of components.